Cheap Price E-Glass Fiber Glass Chopped Strand Mat with Powder/Emulsion Binder

Basic Info

Model No.: EMC/EMCL

Product Description

Model NO.: EMC/EMCL Technique: Chopped Strand Fiberglass Mat (CSM) Fiberglass Type: E-Glass Sample: Provide Free Sample Specification: 100g/m2 HS Code: 7019390000 Certification: BSCI, CCC, CE, CSA, FCC, GS, ISO, RoHS, SAA, SGS, UL Mat Type: Continuous Filament Mat Width Range: 200mm-3600mm Trademark: HAISAN Origin: China Cheap price e-glass fiber glass Chopped Strand Mat with powder/Emulsion Binder

E-Glass Chopped Strand Mats

Product Description:

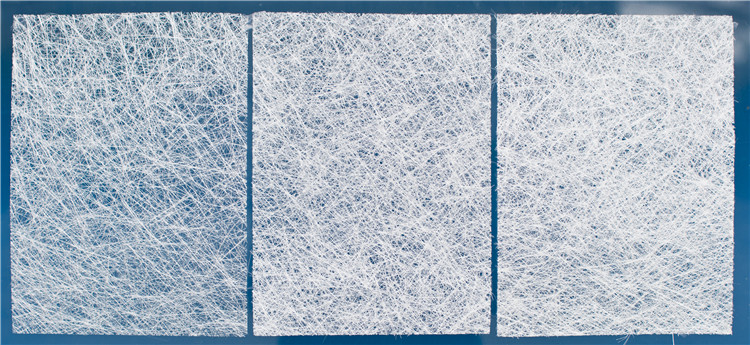

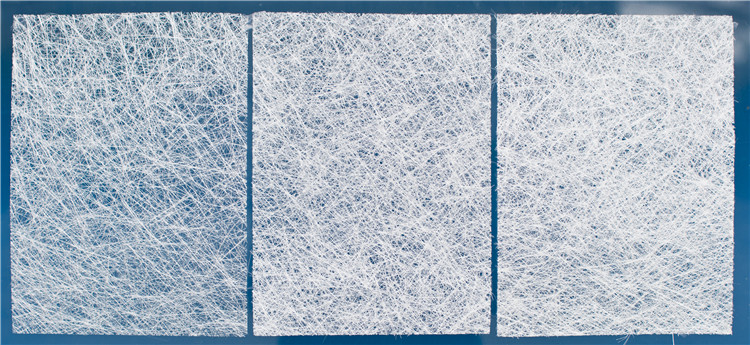

E-glass chopped strand mats are an unwoven fabric consisting of randomly distributed chopped strands held together with a powder or emulsion binder. Compatible Resins and Applications

Strand:

E-glass chopped strand mats are compatible with unsaturated polyester, vinyl ester, epoxy resins.

The products are most widely used in hand lay-up process and can also be used in filament winding, compression molding and continuous laminating processes. The typical end-use applications include various panels, boats, bathroom equipment, automotive parts and cooling towers.

Car mat:

E-glass chopped strand mats are mainly used in polyurethane resin.

E-glass light weight chopped strand mat are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

The products are most widely used in automobile inner headliners with any width less than 3.6 meters, improve it's stiffness and bond strength of polyurethane foam film. The product have excellent process performance, it can lower the weight of automobile based on meet the mechanical and physical properties for headliners.

Product Features

1, Uniform density ensures consistent fiberglass content and mechanical properties of the composites products.

2, Uniform powder distribution ensures good mat integrity, little loose fibers and small roll diameter.

3, Excellent flexibility ensures good moldability with no springback at sharp angles.

4, Fast and consistent wet-out speed in resins and rapid air lease reduce resin consumption and production cost and enhance productivity and mechanical properties of the end products.

5, The composite products have high dry and wet tensile strength and good transparency.

Technical Parameters

E-glass powder chopped strand mat

E-glass Emulsion chopped strand mat

Note:

E-glass Chopped Strand Mats are available with a width range of 200mm~3200mm.Other specifications are also available on customer request.

Packaging

Each Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 79mm.The mat roll is wrapped with plastic film, and then packed in a cardboard box. The roll can be vertically or horizontally placed. For transportation, the rolls can be loaded into a container directly or on pallets.

Storage

Without special requests, Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always at 15ºC-35ºCand 35%-65% respectively. Photos show:

Production line:

Loading:

Loading:

Certificate:

Certificate:

FAQ:

Contact us if you need more details on Powder Binder. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Emulsion Binder、Multi-Split Roving. If these products fail to match your need, please contact us and we would like to provide relevant information.

E-Glass Chopped Strand Mats

Product Description:

E-glass chopped strand mats are an unwoven fabric consisting of randomly distributed chopped strands held together with a powder or emulsion binder. Compatible Resins and Applications

Strand:

E-glass chopped strand mats are compatible with unsaturated polyester, vinyl ester, epoxy resins.

The products are most widely used in hand lay-up process and can also be used in filament winding, compression molding and continuous laminating processes. The typical end-use applications include various panels, boats, bathroom equipment, automotive parts and cooling towers.

Car mat:

E-glass chopped strand mats are mainly used in polyurethane resin.

E-glass light weight chopped strand mat are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

The products are most widely used in automobile inner headliners with any width less than 3.6 meters, improve it's stiffness and bond strength of polyurethane foam film. The product have excellent process performance, it can lower the weight of automobile based on meet the mechanical and physical properties for headliners.

Product Features

1, Uniform density ensures consistent fiberglass content and mechanical properties of the composites products.

2, Uniform powder distribution ensures good mat integrity, little loose fibers and small roll diameter.

3, Excellent flexibility ensures good moldability with no springback at sharp angles.

4, Fast and consistent wet-out speed in resins and rapid air lease reduce resin consumption and production cost and enhance productivity and mechanical properties of the end products.

5, The composite products have high dry and wet tensile strength and good transparency.

Technical Parameters

E-glass powder chopped strand mat

| Property | Area weight(%) | Moisture content(%) | combustible content(%) | tensile strength(N) | Width(mm) | Mark |

| Test Method | ISO 3374 | ISO 3344 | ISO 1887 | ISO 3342 | ISO 5025 | Application |

| EMC60 | ±5 | ≤0.20 | 12-16 | ≥70 | ±5 | Automobile inner headliner |

| EMC80 | ±5 | ≤0.20 | 12-16 | ≥80 | ±5 | |

| EMC100 | ±5 | ≤0.20 | 10-13 | ≥100 | ±5 | |

| EMC120 | ±5 | ≤0.20 | 8-12 | ≥120 | ±5 | |

| EMC225 | -5/10 | ≤0.20 | 4.5±0.9 | ≥80 | ±5 | |

| EMC300 | -5/10 | ≤0.20 | 4.0±0.8 | ≥100 | ±5 | |

| EMC450 | -5/10 | ≤0.20 | 3.8±0.8 | ≥140 | ±5 | |

| EMC600 | -5/10 | ≤0.20 | 3.8±0.8 | ≥160 | ±5 | |

| EMC900 | -5/10 | ≤0.20 | 3.5±0.7 | ≥180 | ±5 |

E-glass Emulsion chopped strand mat

| Property | Area weight(%) | Moisture content(%) | combustible content(%) | tensile strength(N) | Width(mm) | Mark |

| Test Method | ISO 3374 | ISO 3344 | ISO 1887 | ISO 3342 | ISO 5025 | Application |

| EMCL60 | ±5 | ≤0.20 | 10-14 | ≥80 | ±5 | Automobile inner headliner |

| EMCL80 | ±5 | ≤0.20 | 10-14 | ≥100 | ±5 | |

| EMCL100 | ±5 | ≤0.20 | 8-11 | ≥120 | ±5 | |

| EMCL120 | ±5 | ≤0.20 | 6-10 | ≥150 | ±5 | |

| EMCL225 | -5/10 | ≤0.20 | 3.5±0.9 | ≥80 | ±5 | |

| EMCL300 | -5/10 | ≤0.20 | 3.2±0.8 | ≥100 | ±5 | |

| EMCL450 | -5/10 | ≤0.20 | 3.0±0.8 | ≥140 | ±5 | |

| EMCL600 | -5/10 | ≤0.20 | 2.8±0.6 | ≥160 | ±5 | |

| EMCL900 | -5/10 | ≤0.20 | 2.6±0.6 | ≥180 | ±5 |

Note:

E-glass Chopped Strand Mats are available with a width range of 200mm~3200mm.Other specifications are also available on customer request.

Packaging

Each Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 79mm.The mat roll is wrapped with plastic film, and then packed in a cardboard box. The roll can be vertically or horizontally placed. For transportation, the rolls can be loaded into a container directly or on pallets.

Storage

Without special requests, Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always at 15ºC-35ºCand 35%-65% respectively. Photos show:

Production line:

Loading:

Loading: Certificate:

Certificate:

FAQ:

| Q1. May I have the sample for testing? |

| A:Yes, we are glad to provide free samples within 3 days. |

| Q2.Can we use our own logo or design for sticker? |

| A:Yes,you can , you can contact with the salesman, please send an email to her /him and tell. |

| Q3.What certification do you have? |

| A:CE, ISO9001, ISO14001, OHSAS18001 etc. |

Product Categories : Chopped Strand Mat

Premium Related Products

Other Products

Hot Products

Density 48*46 Ends/Inch Window Blind Components Solar Shade Fabrics for BusinessPlastic Grass PaverE/C-Galss Fiberglass MeshPVC Coated Polyester Geogrid12mm Micro PP Polypropylene Fiber Virgin Monofilament PP Fiber Asphalt Concrete Fiber,Bitumen Coated Fiberglass Geogrids Composite with GeotextilePP, HDPE Uniaxial Geogrids for Roadbed with High Tensile Strength, GeoridHDPE 3D Composite Drainage Geonet, Three-Dimension Compound Drainage NetGeomat, Green Mat, 3D Geomat, Geomat for Slope Protection and Erosion ControlHDPE Geocell Price Used in Road Construction for Slope ProtectionHDPE Pond Liner GeomembranePVC Waterproof Membrane with Reinforced Polyester FiberGcl for Construction and Real Estate/Landfill/Man-Made Lake/PoolBitumen Coated Fiberglass Geogrid 50/50kn/M for Asphalt ReinforcementPolypropylene Biaxial Geogrid for RoadHigh Way Road Construction Geotextile